Project Description

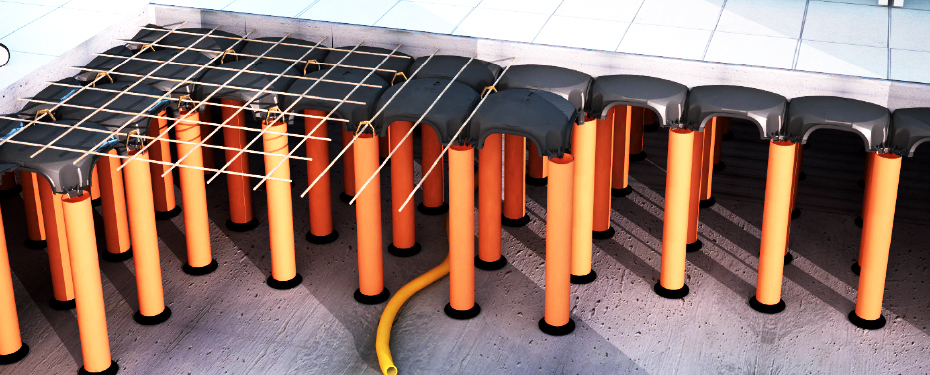

TUBES is a modular system, used for building crawl spaces, ventilated floors and cavities, in the construction or renovation of residential and industrial buildings. it is ideal for the construction of dispersion tanks or rainwater tanks for the collection and reuse of rain water for fire fighting, irrigation or for all uses that do not require the use of drinking water.

.

.

TUBES is manufactured with plastic derived from recycled plastic from post-consumer and industrial waste.

The use of recycled materials saves a lot of issues, just think that for every kg of recycled plastic saves 1.5 kg of CO2.

The TUBES system is used when the height of the crawl space is such that monoblock formworks cannot be used or when special or variable measures are required, as in the case of inclined planes or multilevel surfaces.

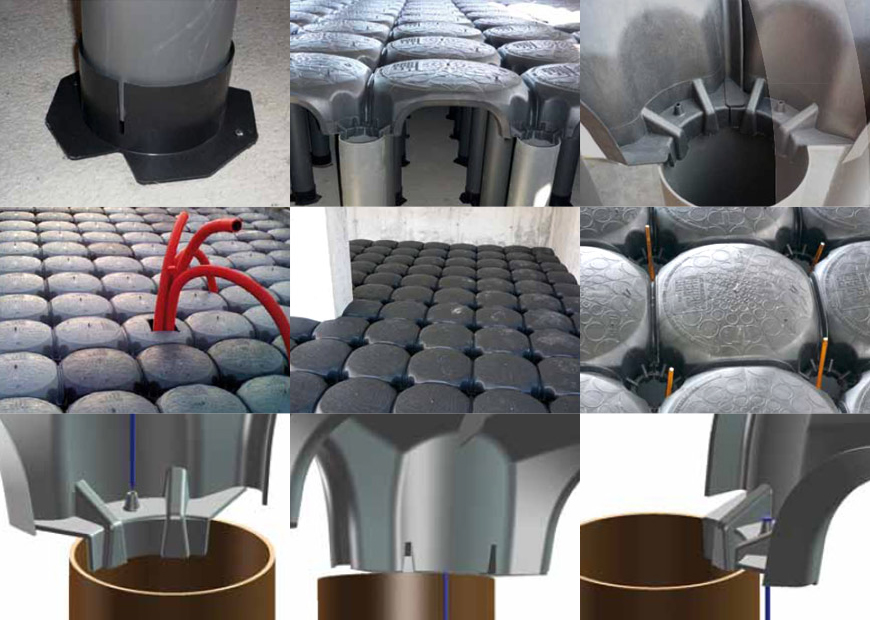

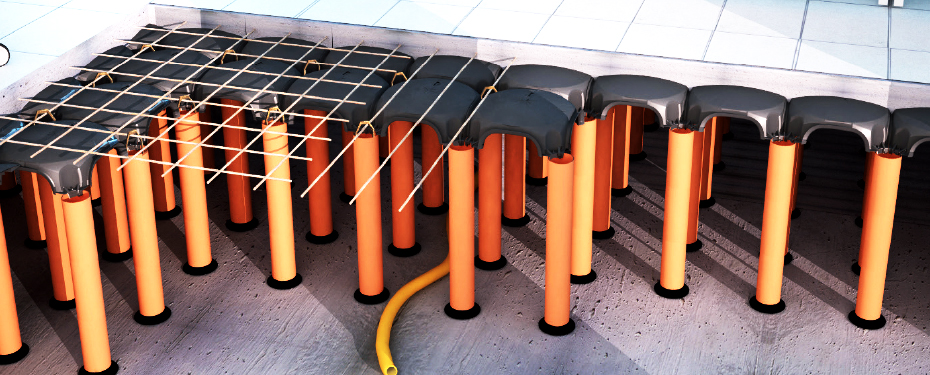

The TUBES systemTUBES system consists of three elements::

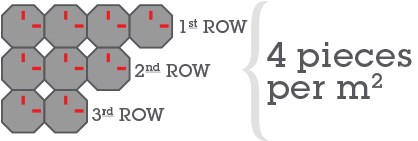

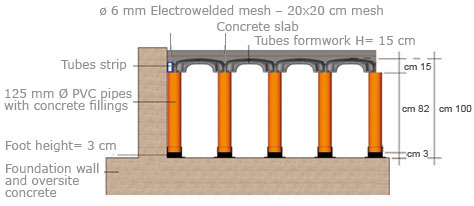

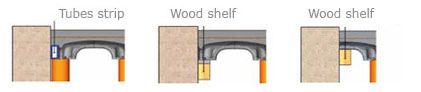

- a square 50 x 50 cm formwork 15 cm high, equipped with a joining system of overlapping modular elements each of which connects with the next.

- a support foot of 3 cm, which is the base for the tube.

- a tube with a diameter of 125 mm.

TUBES is generally installed on a lean concrete subbase of varying thickness depending on the application. After the laying of a suitable mesh and reinforcing rods for the pillars, the concrete is cast and many pillars with the same diameter are formed. Once the concrete is cured, the pillars determine the actual resistance of the floor, with the uniform distribution of loads over the entire surface.

The TUBES system creates a plumbing space with an appropriate steam barrier for the floor and, when properly ventilated by pipes connected with the outside, functions as a vehicle for the disposal of Radon gas.

TUBES has a spherical shape. This feature allows the structure to work in an arc (single compression of the concrete), thus the maximum mechanical strength with minimum thickness of concrete can be achieved, ensuring a considerable saving in materials. The spherical shape of the cap allows for the instant identification of the section of minimum thickness of concrete. In this way, the necessary contraction joints can be made at that section, with the absolute guarantee of control of shrinkage cracks.

MAX HEIGHT: 300 cm

PLUS

- Quick and easy assembly and installation

- Reduction of labour time

- It can be walked on during the work phase

- Saves concrete

- Ability to withstand high loads by adjusting the reinforcement of the pillars

- Adaptation for out of square areas by cutting the elements

- Natural or forced ventilation across the whole surface

- Passage of the systems under the floor in all directions

- crawl spaces, ventilated crawl spaces, cavities and floors in residential and industrial buildings which are under construction or being renovated;

- plumbing spaces;

- floating floors;

- urban redevelopment in general (pavements, squares, etc.);

- sports centres;

- ecological systems and platforms;

- cold roms, drying roms, water recycling greenhouses;

- underground chanels;

- dispersion and rainwater tanks;

- inclined planes or multilevel surfaces;