Project Description

TOTI is a disposable recycled polypropylene formwork used as a modular element for the creation of foundation rafts and slabs made of reinforced concrete.

.

.

Toti is manufactured with recycled plastic derived from post-consumer plastic waste and industrial waste.

The use of recycled materials saves a lot of issues, just think that for every kg of recycled plastic saves 1.5 kg of CO2.

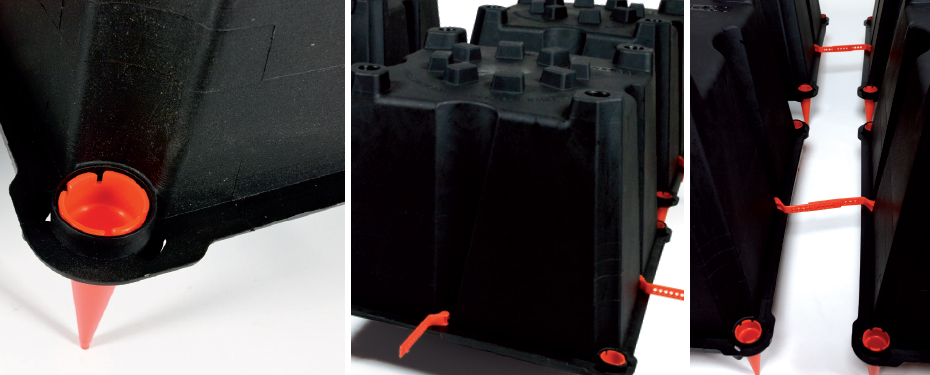

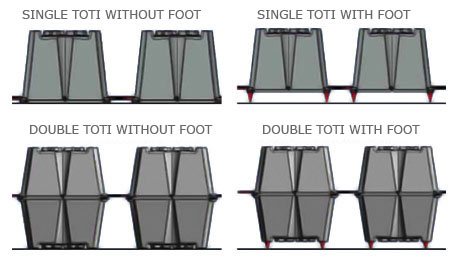

TOTI can be used single or double, by fitting two elements together. The side tabs allow the elements to be attached to the desired centre distance.

It can be used in the thickness of the floor with only the upper cap or, with the help of the tapered feet, floors can be made with top and bottom plates of reinforced concrete in various thicknesses.

By immersing the TOTI formworks in the concrete casting, a lattice of mutually orthogonal beams which are closed above and below by a flat plate is created. This will identify resistant “T” sections in the case of the top plate and “I” sections in the case of the top and bottom plate.

In the case of a double plate, there are two concrete laying phases to be carried out one after the other, to avoid the floating of the elements due to the counter-pressure of the self-compacting liquid concrete.

SINGLE: 16 – 20 – 25 – 30 cm

DOUBLE: 32 – 36 – 40 – 41 – 45 – 46 – 50 – 55 – 60 cm

This solution of relief is highly competitive in structural solutions that necessitate a bidirectional plate behaviour and the ribs identified by the position of these products form a lattice of beams of the same geometry that greatly reduces stresses and strains. Furthermore, to simplify the reinforcement in the floor edge areas, by the pillars or walls, concrete filled areas are provided for to contrast negative moment stresses and shear stresses. In such a way, large span floors can be made which can withstand heavy loads while using smaller quantities of concrete and steel.

PRODUCT PLUS

- It enables building one-way or two-way floors.

- Reduction of floor thickness.

- Up to 40% reduction of the weight and consequent load reduction on the foundations.

- Reduction in the consumption of concrete and steel.

- Reduction of the number and section of the pillars.

- It does not require beams between the pillars, as it has a very similar behaviour to that of the plate and a perimeter curb is usually sufficient.

- Greater static performance and floors with greater spans (up to 20 metres).

- Antiseismic: reduction of the seismic mass of the floor system.

- Quick and easy to lay.

- It can be walked on during construction (it supports a concentrated load > 200 kg).

- Stackable and modular (the tapered feet are removable and easily replaced).

- Architectural flexibility.

- Civil and residential buildings;

- Offices, commercial and industrial buildings;

- School buildings;

- Hospitals;

- Car parks;

- Civil and industrial renovations.

ANTISEISMIC BUILDINGS

Floors and raft foundations made with the TOTI disposable formwork comply with the provisions of the new Technical Construction Standards (DM14/01/2008).

FLOORS: The floors meet all general requirements for structures in reinforced concrete and those specific to floors (§ 4.1.9.2 for floors fully laid on site and § 4.1.9.3 for those which are partially prefabricated). Enable the design of floors with the necessary characteristics of ductility and deformation capacity, with good possibilities for the redistribution of seismic actions and rigidity in the plane.

RAFT FOUNDATION: thanks to the excellent static performance, it helps overcome the limits and complications related to the isolated foundations required in earthquake zones. Indeed, the new law requires the necessity of connection between the plinths, whether in the case of superficial or deep foundations (moreover, the connection must be achieved at a distance of not over 1m from the laying level of the foundation plinth).