Project Description

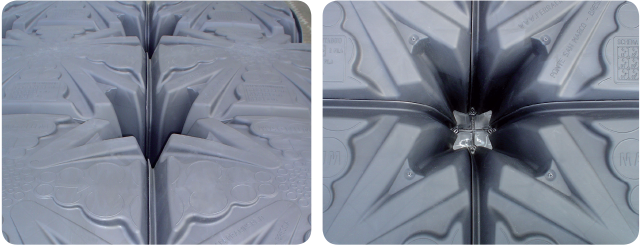

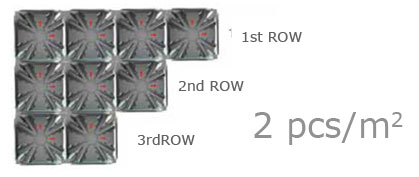

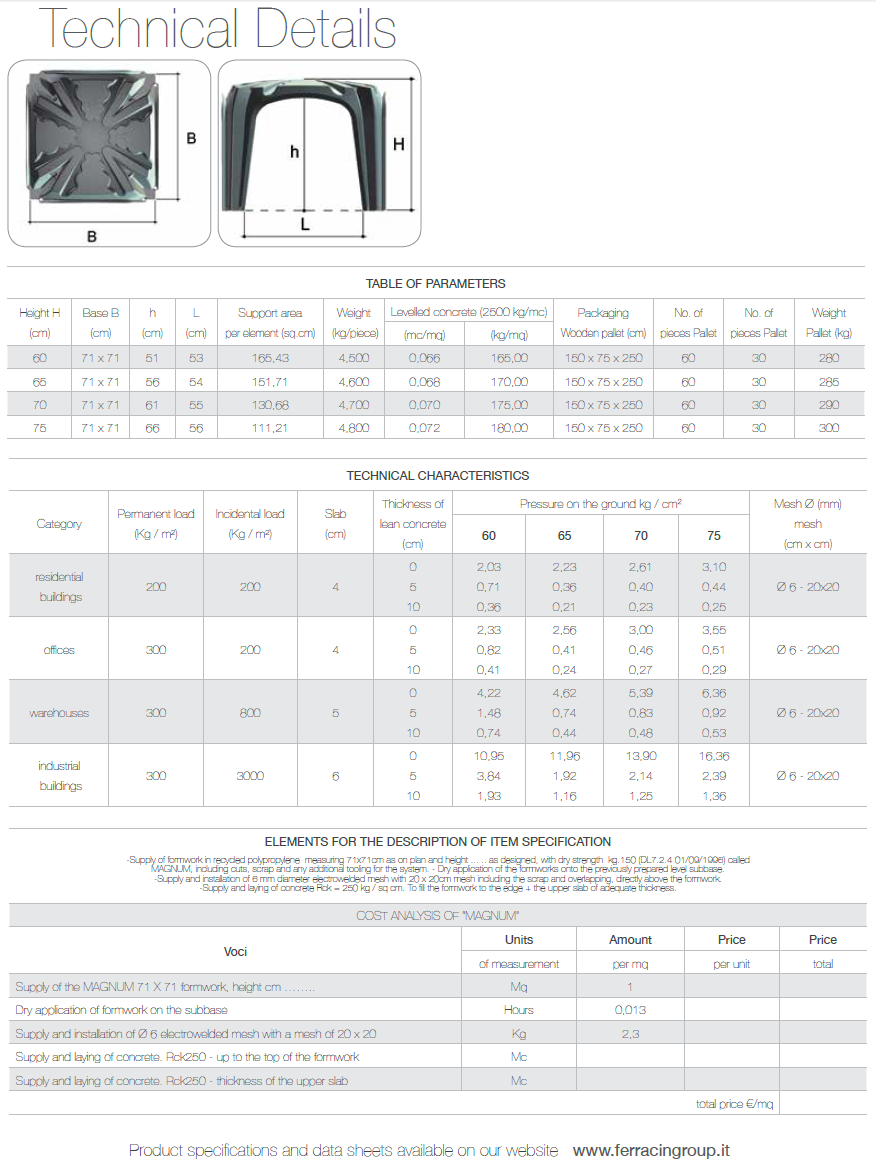

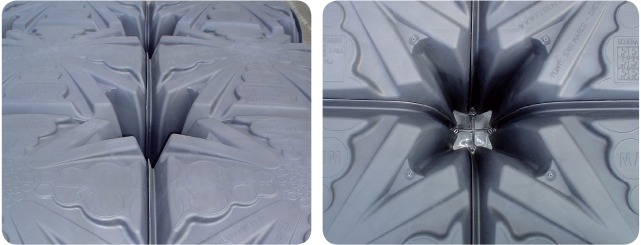

Magnum is an innovative system for creating crawl spaces, floors and ventilated cavities in general. It is an element of a square 71 x 71 cm, equipped with a versatile system of interlocking with the overlap of a modular element with the next. There is an interlocking safety that prevents the legs from opening during the casting stage. On each form there are directional arrows and the assembly diagram indicating the correct direction of laying.

.

.

MAGNUM is manufactured with plastic derived from recycled plastic from post-consumer and industrial waste.

The use of recycled materials saves a lot of issues, just think that for every kg of recycled plastic saves 1.5 kg of CO2.

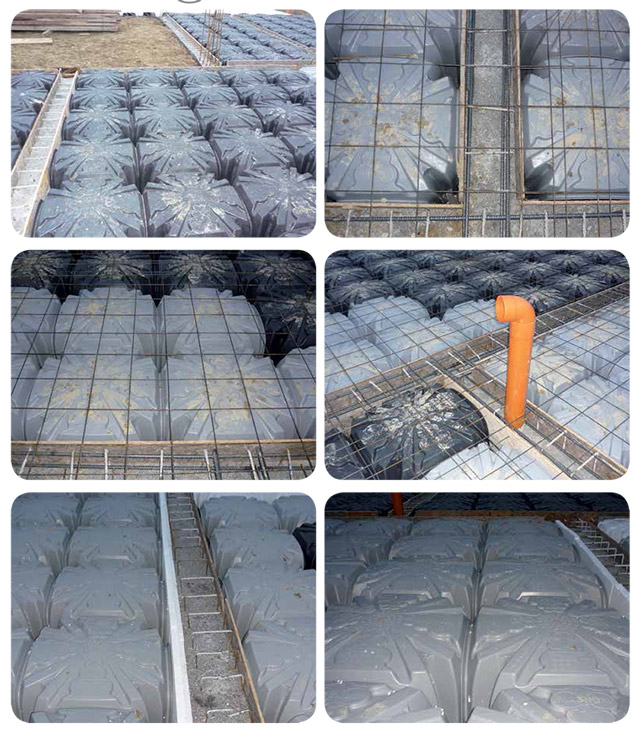

With MAGNUM a safe platform which can be walked on is created and over this the concrete is cast.

MAGNUM is generally installed on a foundation of lean concrete of varying thickness depending on the situation. After the laying of a suitable mesh, proceeding with the casting of concrete, many pillars are formed which, once the concrete is cured, determine the actual resistance of the floor, with the uniform distribution of loads over the entire surface. MAGNUM is used in new constructions or in renovations of residential and industrial buildings.

MAGNUM creates a plumbing space with an appropriate steam barrier for the floor and, properly ventilated by pipes connected with the outside, a vehicle for the disposal of Radon gas.

GAS RADON

Radon gas is a radioactive gas, which is colourless and highly volatile, produced by some of the rocks of the earth's crust and therefore present in different concentrations in all types of terrain.

in areas where the ground is particularly rich in this element, closed environments can favour the build-up of high levels of radon which are dangerous to humans.

The ventilated crawl space, allowing air flow under the building, allows the release and dispersion of RADON GAs into the atmosphere, thus avoiding it reaching the rooms which are lived in.

MAGNUM has a spherical shape: this feature allows the structure to work in an arc, (single compression of the concrete) allowing maximum mechanical strength with minimum thickness of concrete, ensuring considerable saving in materials. The spherical shape of the cap allows for the instant identification of the concrete section with the minimum thickness. In this way, at that section the necessary contraction joints can be made, with the absolute guarantee that shrinkage cracks can be controlled.

MAGNUM resists a load of 150 kg. This is the minimum limit required by Italian law, since it corresponds to the weight of a person walking on it safely.

Available Heights: 60 – 65 – 70 – 75 cm

PLUS

- Speed a nd simplicity of installation (one person can lay up to 100 square meters in an hour)

- It can be walked on during the work phase

- Reduces labour time by 80%

- Saves concrete

- Adaptation for out of square areas by cutting the elements

- Natural or forced ventilation across the whole surface

- Passage of the systems under the floor in all directions

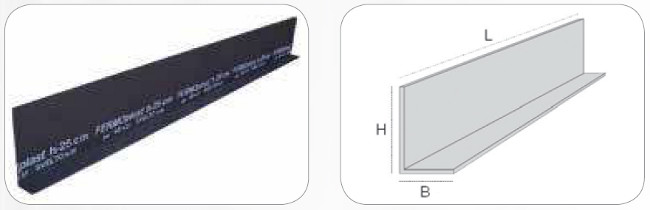

- Ability to create the foundation beams and slab with a single casting using the FERMOplast accessory .

- crawl spaces, ventilated crawl spaces cavities and floors in residential and industrial buildings, new builds or renovations;

- plumbing spaces;

- floating floors;

- urban redevelopment in general (pavements, squares, etc.);

- sports centres;

- ecological systems and platforms;

- cold rooms, drying rooms, greenhouses, rooms at a constant temperature;

- underground channels;